Efficient Reverse Logistics Offers Opportunities for Profit Growth

By Tom Chick

Vice President, National Accounts

Technical Transportation, Inc

Returning purchased items or swapping out existing equipment in the field can be a difficult – and costly process – for everyone, from end-users, to retailers, to manufacturers, and all of the logistical touch points in between.

But it can also present a big opportunity, especially for manufacturers, if they have an efficient reverse logistics process in place.

A recent CBRE Group report indicated that ecommerce returns throughout the U.S. retail industry from just this past holiday roughly equaled $32 billion of retail sales, and these returns accounted for 15-30% of total sales. CBRE also noted that while the number of returns from ecommerce sales continues to grow each year, the process for returns – or reverse logistics – is an intricate process that requires many components, including a precise network of warehouses for handling returns and a robust inventory management system.

While this statistic is noteworthy, routine returns and the need for reverse logistics aren’t limited to the retail industry anymore. They are necessary for any business in any industry, and they are being driven by a variety of factors, including an increase in big data, ongoing labor shortages, an increasing need to cut costs, and consumer pressures to increase speed of delivery while enhancing customer service.

Reverse Logistics for More Complex Products and Technology

That growing demand even reaches into the realm of highly complex equipment and technology.

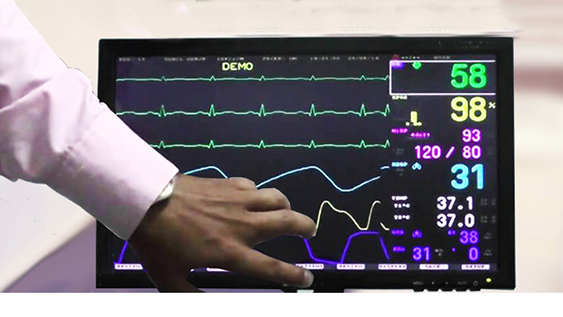

For example, rentals, leases and trade-ins are now commonplace for large medical equipment such as MRI machines, ultrasound equipment and ophthalmology technology, due to the large price tags on those products and the constant upgrades in technologies. So a medical manufacturer must have a reverse logistics program in place in order to swap out older models for newer ones, or to help with any repairs in the field.

The challenge for manufacturers is determining how to manage a reverse logistics program of this big or high-value equipment in a way that accurately values the inventory at the time of pick up, manages customer expectations, and reduces overall costs.

Many companies have tried using their in-house sales teams to handle this process, but it has often produced a disconnect between the sales person's desire to make the customer happy by maximizing the trade-in value of the old product, versus the actual and objective value of the product in its current condition.

Manufacturers have also tried using field service engineers (FSEs), but given the shortage of qualified FSEs, they’ve proven very expensive to the tune of $600-$700 for each "event" on average—with specialty projects as much as $500 per hour or $1,500 per day.

What is working best among many manufacturers of large and complex equipment is the use of 3PL companies that already have reverse logistics capabilities and processes in place. These providers can expertly and cost-efficiently assess the old product’s condition and value, and then help the manufacturer break down, disassemble and return the equipment.

And if a manufacturer can find a 3PL with expertise in their specific industry, further cost savings can be realized due to fewer potential mistakes. The end result is higher efficiency and higher profits both up and down the supply chain.

Need Help?Do you have a reverse logistics need that you need addressed, or do you simply have a question about your current reverse logistics process? We’re happy to help. Click here to contact us today.